Whatever the size of your operations or the scope of your requirement, SKF can provide the appropriate condition monitoring and reliability solution for you. And our solutions can be expanded as your needs grow.

Close working partnerships with customers worldwide have provided SKF with an extensive knowledge of applications in virtually every industry. As a result, we have learned to apply today’s most relevant emerging technologies to industry-specific applications.

Please see below for further information about our products:

Or, for more information, please visit Products/ Condition Monitoring Products on SKF.com

Condition monitoring

SKF offers a range of basic products designed for the user who wishes to begin a low-cost condition monitoring programme. Basic instruments assess and report on temperature, oil condition, speed, bearing condition, shaft alignment, noise, vibration and more.

SKF basic condition monitoring products include:

SKF MicroVibe P

Low-cost, compact, lightweight and feature-rich, the SKF MicroVibe P is the first vibration test and measurement instrument designed to be used with a Personal Data Assistant (PDA).

SKF Vibration Pen Plus

SKF Vibration Pen Plus is a pocket instrument that provides a low-cost multi-parameter approach to condition monitoring.

Our portable monitoring solutions enable maintenance personnel to identify problems on the spot, and collect dynamic machine data which can be analysed offline using our @ptitude Monitoring Suite of software products.

SKF offers a wide variety of portable condition monitoring hardware, including:

SKF Microlog® Analyser MX series portable maintenance instrument

The Microlog MX is, in effect, several instruments combined in a single, fully ruggedised, handheld device. The MX series provides users the flexibility to choose from a range of different testing and analysis applications. The MX modular analysis tools include:

-

A conformance check module to assess machinery health in accordance with industrial standards (ISO, BS, API etc) or enable users to define their own standards.

-

An easy to use FFT analyzer with on-screen phase vector readout

-

A stand alone balancer (static & dynamic couple, single or dual plane)

-

A bump test for determining resonance

-

A digital signal recorder

-

Run up, coast down

SKF Microlog® Analyser GX series data collector/FFT analysers

The SKF Microlog® Analyser GX series data collector/FFT analyzers are designed to enable a user to establish a comprehensive periodic condition monitoring program.

With its large colour-rich display and powerful, modular platform, the GX series advances portable vibration instruments to the next generation of data collectors/analysers. In addition to its full featured route and non-route condition monitoring and analysis features, the GX series can leverage the same modular analysis tools as the microlog MX.

SKF Microlog Analyser CMXA 51-IS – ATEX – intrinsically safe portable data collector/FFT analyser

The SKF Microlog Analyser CMXA 51-IS, an intrinsically safe, rugged and portable, hand-held instrument, enables collection of vibration, process, and dynamic data in hazardous environments. Such industries include petrochemical, water treatment and pharmaceutical, as well as others where IS regulations apply.

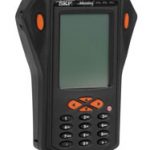

SKF MARLIN® I-Pro

The SKF MARLIN I-Pro is part of the SKF family of hand-held mobile computers for Operator Driven Reliability (ODR). ODR, the framework for organizing the activities of plant operations personnel, is key to an organization’s reliability maintenance programme. The MARLIN system is the frontline tool for operators, improving reliability and safety through better communication with the plant wide team.

The new MARLIN I-Pro is a rugged, high performance data collector that enables plant operations personnel to quickly and easily collect, store and analyse overall machine vibration, process and inspection data. The unit enables trending, comparison with previous readings, alarm alerts and more. A “user notes” feature enables an operator to immediately record detailed observations of troublesome machine conditions or questionable measurements.

Our on-line systems are excellent for continuous monitoring of critical plant equipment, equipment where access is difficult, or where user safety is at risk.

When on-line machine condition monitoring is the choice, SKF can deliver a comprehensive product range and field service backed by decades of field experience.

-

On-line monitoring systems for automated periodic data collection

-

Protection systems for real-time monitoring and protection of critical machinery (conforming to API 670)

-

Single-channel transmitters for low-cost continuous monitoring and protection

-

Wireless systems to improve machine reliability, reduce installation costs and increase personnel safety

Consisting of three modules – Analyst, Inspector, and Observer – the SKF @ptitude Monitoring Suite forms the basis for a completely integrated approach to condition monitoring. With a familiar WindowsTM interface, this powerful software accepts data from the full range of SKF data collection devices and interfaces with SKF @ptitude Decision Support to facilitate consistent and reliable decision-making.